Particle Shadow Velocimetry

Particle Shadow Velocimetry

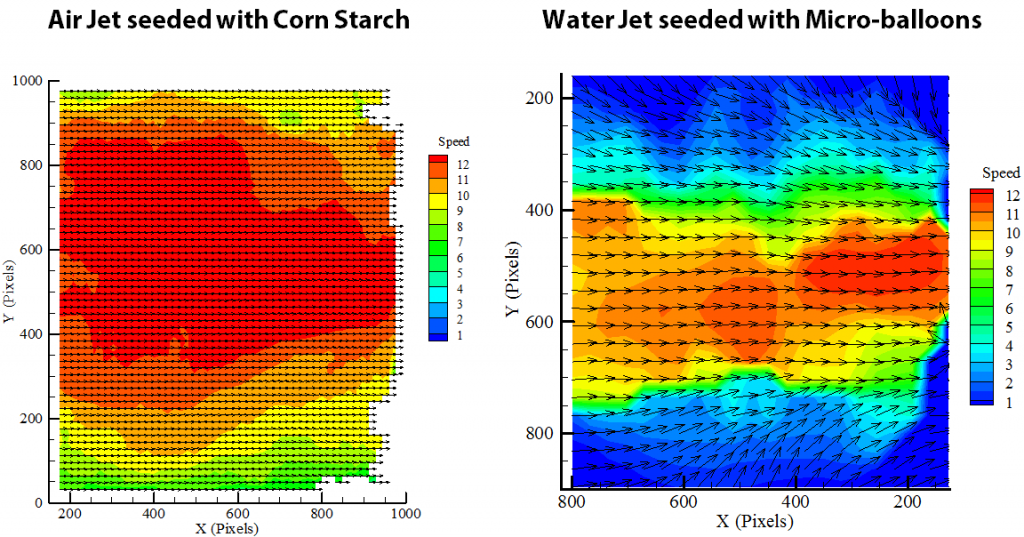

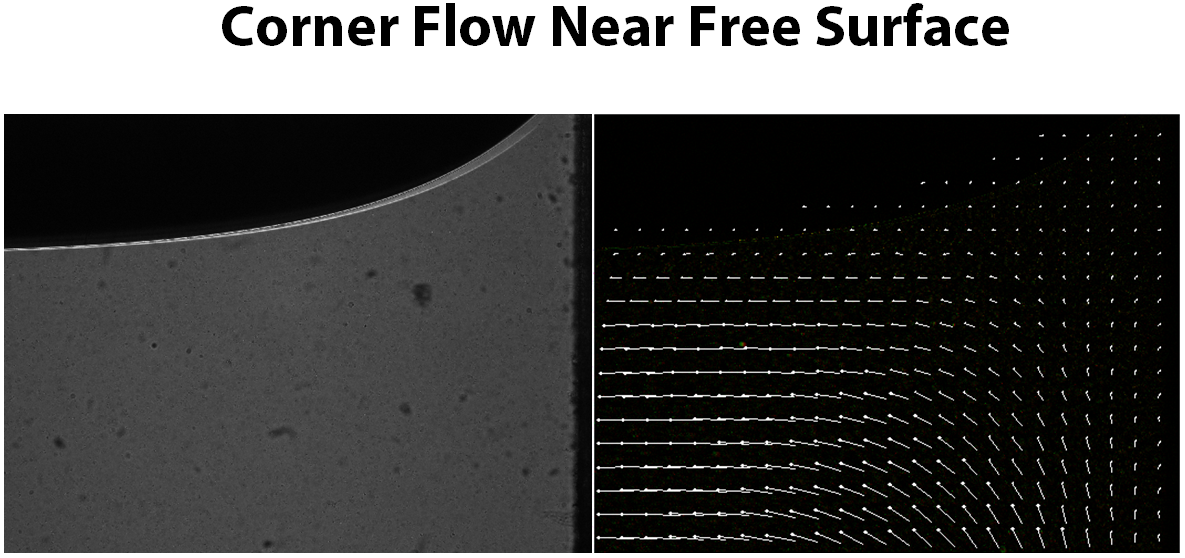

Particle shadow velocimetry (PSV) is a novel technique that shares many of the attributes of microPIV and Forward Scatter PIV (fsPIV). It utilizes low-power pulsed LED light sources to measure the displacement of seed particles in a flow. PSV images can also be used to characterize particle parameters such as size and shape. Since this is a volumetric illumination technique, it relies on the receiver optics to optimize the depth of field for the measurement. Any pulsed light system can be used as the light source; however, LEDs are particularly well suited since they can be over-driven in a short-pulse mode to produce intense sub-microsecond light pulses. Furthermore, the use of LEDs combined with a high speed camera results in a high-speed system with bandwidth of 10’s of kHz. Because the technique does not rely upon weak-particle light scattering, lasers are neither necessary nor recommended for use with this approach.

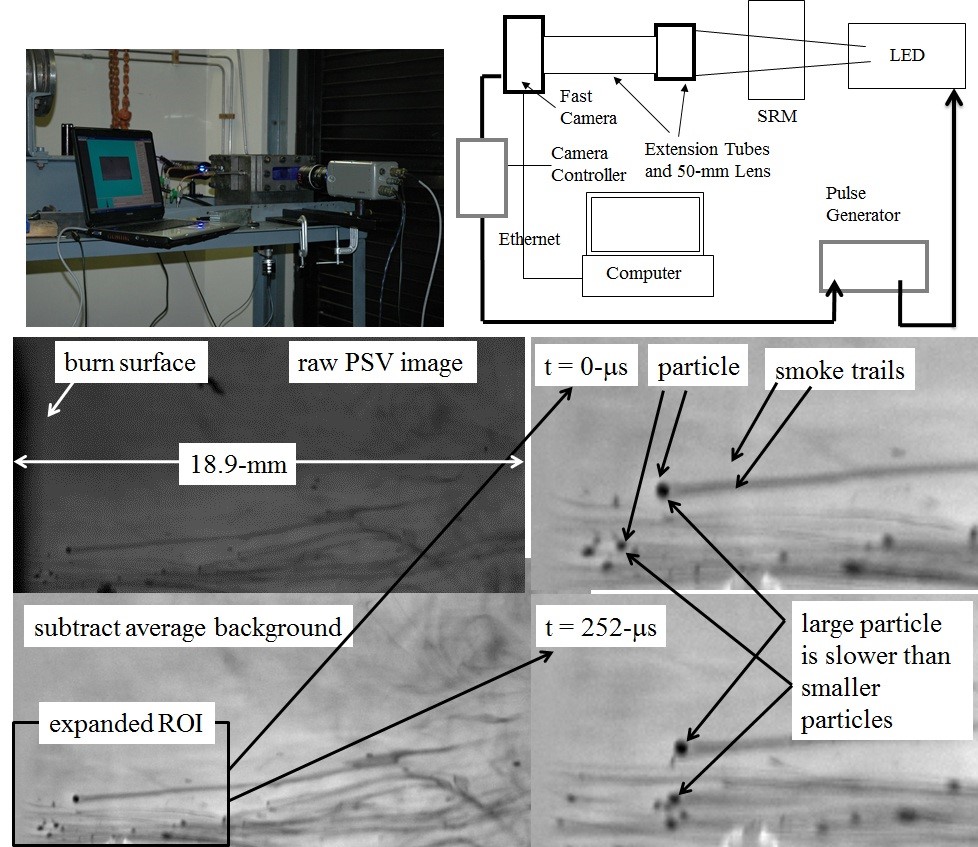

The general layout of the PSV instrument is shown in the Figure. Light from a pulsed LED source is directed through the measurement area onto a camera (interline-transfer, color, or high speed). This inline arrangement allows the shadows created by the particles that are suspended in the flow to be recorded along with their forward scatter. For the most part, the forward scatter is small compared to the extinction caused by the particle; however, in certain situations the forward scatter can be large in amplitude (large transparent particles for example).

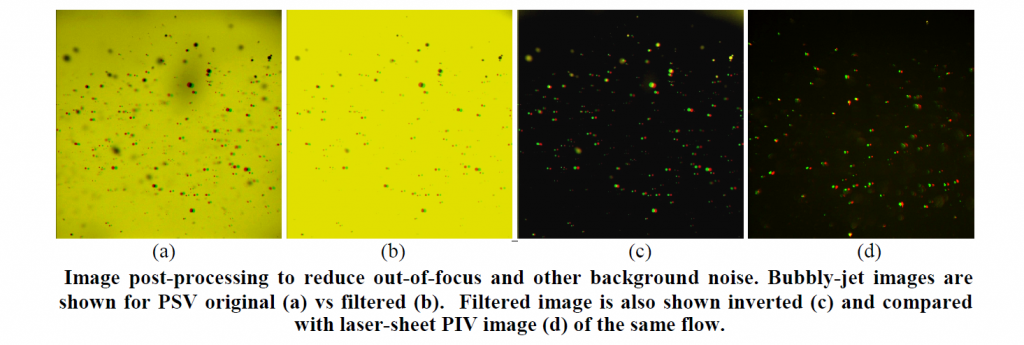

After the particle shadow images are recorded at two separate times, they are processed by the standard correlation approach to obtain velocities. In most cases some pre-processing of the image is necessary to minimize the measurement volume and enhance the signal to noise of the particles. This procedure includes squaring the image to enhance the edges of in focus particles and inverting the image to produce a negative. The resulting image appears very similar to a standard PIV image, and in fact, can be processed using general PIV software.

With the availability of off-the-shelf PIV systems, why is PSV of interest? PSV offers several advantages over traditional PIV systems.

- PSV is a low cost option. PSV utilizes LEDs rather than Lasers, and therefore, the cost of the equipment is significantly lower. It is also noted that the use of an LED rather than a Laser has significant safety advantages.

- LEDs can be pulsed at 10’s of kHz and therefore, data can be obtained at these high rates without the use of an expensive Laser.

- Finally, PSV uses volumetric illumination, this eliminates the strong scattering from the surface which can saturate the camera when using PIV. PSV, like every other experimental technique has limitations. The most significant issue for PSV is probe volume. As it is necessary to image individual particles the field of view is limited by a combination of the particle size and number of pixels on the camera.

Fluid Flow

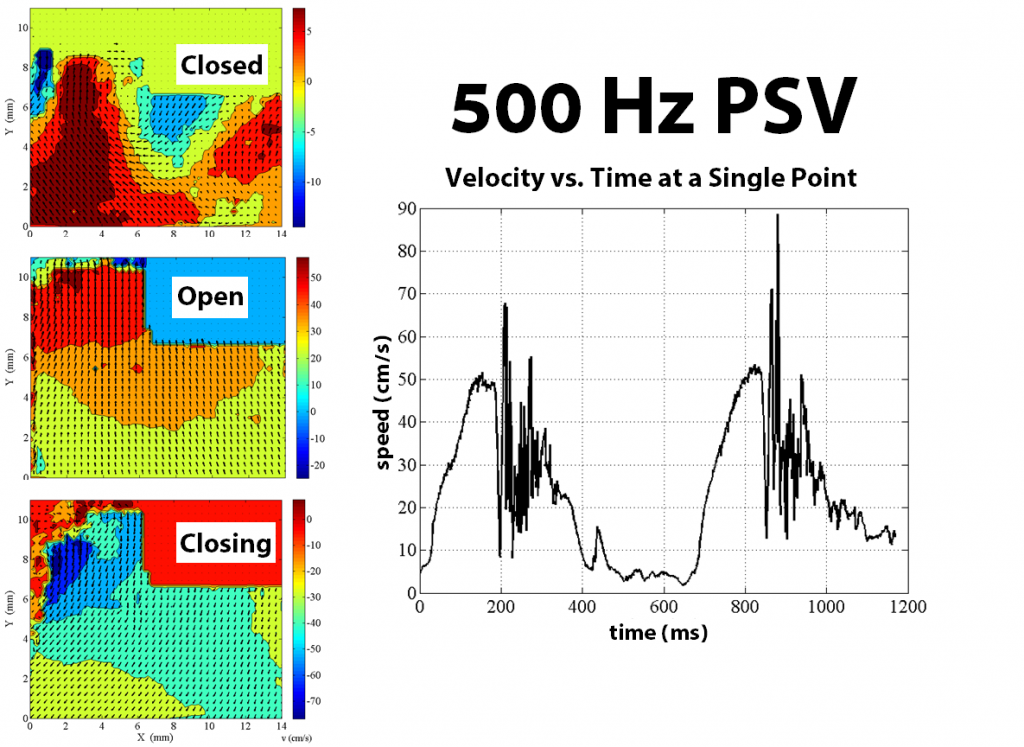

PSV was used to measure the velocity of a jet moving past a tab. This experiment seeks to model sound generation. The data presented here was acquired at 500-Hz using a CCD camera. The mean image represents an average of about 2,000 samples. The pulsating nature of the jet in the time series images is likely due to the jet flapping transverse to the plane of the measurement. Data is being acquired in the core of the jet, and on the boundary, thus the regions of lower velocity.

Biomedical

In this application, PSV is used to acquire 2D velocity data on an artificial valve. The images on the left show the flow at three instances in the operating cycle of the valve. The entire sequence is shown in the movie on the lower right side. The data at a point, throughout the cycle is shown in the top view. It is worth noting that the time history of the flow is relatively repetitive but not exactly periodic. Acquiring a sequence of data on this valve using a phase-lock technique may provide inaccurate information on the flow. The ability to acquire image-based data on the flow in a continuous time sequence is of substantial value.

Combustion

PSV data was acquired in a solid rocket motor. The goal is to track particles of solid rocket motor (SRM) fuel as they break off from the burn surface. These particles continue to burn as they enter the main flow, and they agglomerate with other particles. These large particles erode the throat of the SRM, and thus, the thrust profile of the rocket is modified. In this case, the data was acquired at 15-kHz.

A sequence of the strand burner data was processed using a filter to isolate particles. The resulting compilation of the 100 image sequence is shown in the Figure. Notice the ease with which the large particles can be identified as they move from the surface out into the flow. The size, position, and velocity of these particles can be processing using this single set of images. The figure also includes a histogram of particle size for this sequence of images. Finally, notice the ability of the PSV technique to acquire data right at the burn surface.

PSV References

- Kilo-Hertz Color Particle Shadow Velocimetry

- PIV with LED Particle Shadow Velocimetry

- Particle Shadow Velocimetry In Pulsed Detonation Engine

Packaged PSV Systems

For ordering information please contact our sales department: [email protected] or call us at (937) 630-3012

For technical support, please contact our support department: [email protected] or call us at (937) 630-3012