Pulsed Detonation Engine

Pulsed Detonation Engine

What is PDE

PDE stands for Pulsed Detonation Engine. The operational cycle of our PDE is shown in the animation above. First, purge air (blue) is injected into the tube to isolate the exhaust gases from the next fuel/air charge. After this purge process is complete, the tube is filled with a premixed gaseous combination of fuel and air (green). The valves close, and a conventional automotive spark plug ignites the mixture, causing it to deflagrate. Deflagration is the familiar everyday combustion observed when a match is struck. At this point, the operation of a PDE begins to differ from that of a conventional engine.

The deflagration wave, through a process called deflagration-to-detonation transition (DDT), is accelerated into a phenomenon known as detonation. Unlike a deflagration, which travels at subsonic speeds and only produces peak pressure rises of two to three times atmospheric pressure, a detonation travels at Mach 5-6 and produces peak pressure rises of 30 to 100 atm. After a very short amount of time, the detonation wave passes out of the tube, leaving high-pressure and –temperature gas in the detonation tube. The expulsion of this high-energy gas produces thrust. On the flight project engine, 20 detonations are produced in each of four tubes each second. Thus, 80 detonations occur each second. These rapid pulses of force produce the thrust to propel the aircraft.

Didn’t the Germans already construct operable PDE’s?

No. During World War II, Germany, and later the United States, outfitted several weapon systems with engines called pulsejets. The premise of a pulsejet is very similar to that of a PDE. However, in a pulsejet the fuel is deflagrated rather than detonated. Deflagrations only produce peak pressure rises of 2-3 atm and occur at subsonic speeds. On the other hand, detonations produce peak pressure rises of 30 or more atm and propagate at Mach 5 or faster. Thus, while sharing the low cost and simplicity of PDE’s, pulsejets do not achieve the high efficiencies and supersonic operating range associated with PDE technology.

Why spend money on PDE research?

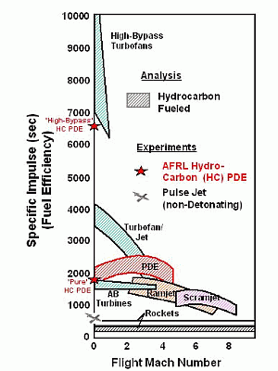

PDE’s offer a wide range of potential payoffs to both military- and commercial-engine consumers. First, as shown in the graphic on the right, PDE’s have a much wider efficient-performance range than jet engines. In fact, it is predicted that PDE’s will maintain excellent efficiency over the entire range from static thrust to Mach 4.

While less efficient than jet engines at low speeds, PDE’s provide higher performance at high Mach numbers. In the range Mach 2-4, no other engine technology boasts higher performance. In addition, unlike scramjets or ramjets, which require a separate engine to reach cruising speed, a PDE can takeoff under its own power. Finally, PDE’s contain very few moving parts. Unlike jet engines, which require numerous components machined from special materials and designed to operate at high rotational frequencies, PDE’s are simple and easy to maintain. In fact, the first research PDE’s at Wright-Patterson Air Force Base were constructed almost entirely from off-the-shelf automotive components.

Who is Doing the Work?

ISSI provides several personnel who are key to the flight project, which is a government research project funded by the Air Force Research Laboratory Propulsion Directorate’s Combustion Science Branch. In addition,Scaled Composites consults on the use of their Long EZ aircraft, provides the test pilots, and will perform the flight-testing. The Air Vehicles Directorate at Wright-Patterson Air Force Base shares their expertise on acoustical and vibration measurements and provides additional project funding. Finally, Universal Technology Corporation (UTC) provides several team members in areas of displays and public relations. This program would not be possible without the combined efforts and talents of numerous scientists, engineers, technicians, and administrators who work in industry, study in academia, and serve the U.S. government in or out of uniform.

What are the Goals of the Flight Project?

The goals of the PDE flight project are to propel an aircraft using a PDE, to investigate the acoustical and vibrational impact of a PDE on an airframe and pilot, and to demonstrate the potential of PDE’s to the combustion research community. This demonstration, the first of its kind, represents the first step toward developing PDE’s as a viable propulsion technology.. While the plane will not be “Flight Certified,” an FAA Phase II Airworthiness Certificate will be obtained.

We should point out this is not an engine demo. The PDE has been constructed at low cost and from the perspective of a research, proof-of-concept endeavor. While sufficiently durable to meet FAA/EA oversight and regulations, the engine is not intended for mass production or extended operation. The system has been designed to demonstrate subsonic PDE flight at approximately 200 MPH. The engine is valve-area limited and not designed to demonstrate high thrust capabilities.

Were Car Parts Used on the Research PDE?

Yes, the purpose of this project was to demonstrate the viability of PDE technology, not to explore the optimization of PDE design. Thus, the engine was constructed using low-cost, off-the-shelf automotive components. These parts can be easily replaced and simply modified and are readily available, making them ideal for a research environment.

Does it Work?

Yes, ISSI has successfully fired research PDEs at AFRL/PRTS since 1998, without the use of oxygen-enrichment, high explosives, or excessively lengthy detonation tubes. In fact, while many groups measure their test runs in seconds, the PDEs that ISSI personnel have developed have produced thrust for hours at a time. The worlds first flight of a PDE mounted to a Rattan LongEZ aircraft was successfully completed on January 31st, 2008 by ISSI working with the Air Force Research Laboratory and Scaled Composites. See here for details.