Base Coatings for Pressure Sensitive Paints

Base Coatings

Base coatings are used with select pressure sensitive paints to provide a uniform, opaque background and to improve adhesion to the model surface. Base coatings are also used to mask imperfections on model surfaces, to protect certain materials from the solvents used in pressure sensitive paint application and to protect the pressure sensitive paint from chemical interactions with the model. There are two recommended basecoat options: epoxy-based screen layer and FIB Basecoat™.

Screen Layer

(Product ID: SCR-XXX)

Epoxy Screen Layer is a two-part formulation designed to be applied to surfaces using conventional paint spraying equipment to mask machining marks and stains or to mask surfaces that fluoresce and interfere with PSP or TSP data. Epoxy Screen Layer comes in two parts and is mixed 1:1 by volume. Epoxy Screen Layer provides the highest quality surface screen layer with superior solvent resistance and improved opacity. The solvent resistance means PSP can be applied over it and removed without the need to reapply the screen layer each time. Epoxy Screen Layer needs to be fully cured before the PSP is applied by curing at elevated temperatures (90C for ~4 hours) or by allowing a few weeks to air cure to prevent the screen layer from interacting with the PSP and compromising data. Epoxy Screen Layer is a permanent screen layer. It is recommended for all models but required for plastic models.

Epoxy Screen Layer is a two-part formulation designed to be applied to surfaces using conventional paint spraying equipment to mask machining marks and stains or to mask surfaces that fluoresce and interfere with PSP or TSP data. Epoxy Screen Layer comes in two parts and is mixed 1:1 by volume. Epoxy Screen Layer provides the highest quality surface screen layer with superior solvent resistance and improved opacity. The solvent resistance means PSP can be applied over it and removed without the need to reapply the screen layer each time. Epoxy Screen Layer needs to be fully cured before the PSP is applied by curing at elevated temperatures (90C for ~4 hours) or by allowing a few weeks to air cure to prevent the screen layer from interacting with the PSP and compromising data. Epoxy Screen Layer is a permanent screen layer. It is recommended for all models but required for plastic models.

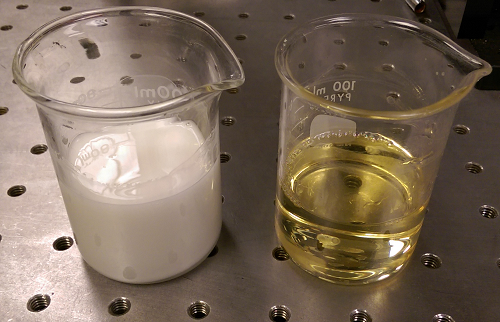

Screen Layer in Two Parts, Before Mixing

Specifications

- Shelf Life: 3-months

- Available quantities: 200-ml, 400-ml, 750-ml

- Surface coverage is approximately 1 square meter per liter.

Downloads

Screen Layer Painting Instructions.pdf

FIB Basecoat™

(Product ID: FB-XXX)

FIB Basecoat™ is a single application base coating that is sprayed onto a model surface with paint spraying equipment to mask machining marks and stains or to mask surfaces that fluoresce and interfere with PSP or TSP data. FIB Basecoat™ also provides a uniformly reflective surface to minimize illumination errors and enhance the emission of PSP and TSP. This formulation is recommended for surfaces where the base coating and PSP or TSP absolutely must be removed from the surface using common mild solvents.

FIB Basecoat™ is a single application base coating that is sprayed onto a model surface with paint spraying equipment to mask machining marks and stains or to mask surfaces that fluoresce and interfere with PSP or TSP data. FIB Basecoat™ also provides a uniformly reflective surface to minimize illumination errors and enhance the emission of PSP and TSP. This formulation is recommended for surfaces where the base coating and PSP or TSP absolutely must be removed from the surface using common mild solvents.

Specifications

- Shelf life: 12-months

- Available quantities: 200-ml, 400-ml, 750-ml

- Surface coverage is approximately 1 square meter per liter.

Downloads

FIB Basecoat™ Painting Instructions.pdf

For ordering information please contact our sales department: [email protected] or call us at (937) 630-3012

For technical support, please contact our support department: [email protected] or call us at (937) 630-3012