Fabrication

Fabrication

At ISSI we have an in-house machine shop for the fabrication of ISSI hardware. We also have a precision CNC machining capacity and capability to take on part requests from outside companies. We have a shop team with over 50 years of experience and 3D modeling software to take parts from concept to reality.

Our shop equipment includes:

- Hurco VM10 CNC Mill

- 2x Hurco VM10i CNC Mills

- Hurco VM20 CNC Mill

- Prototrak CNC Lathe

- Bridgeport 3 Axis

- Sandblasting Cabinets

- Sheet Metal Bending

- Sheet Metal Punch

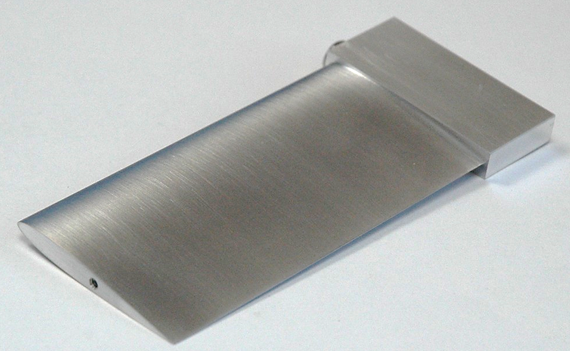

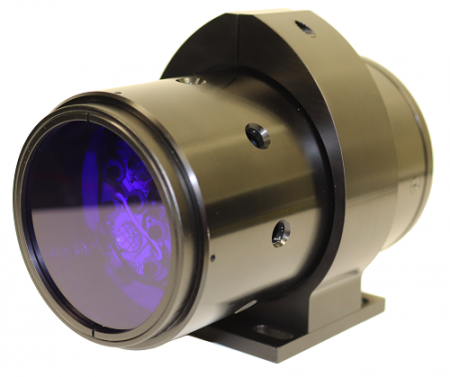

ISSI manufactures most of the mechanical housings and fixtures for our commercial products in our shop. We also offer fabrication services for external customers for a variety of applications. Some of the examples of our work include, but is not limited to:

Wind Tunnel Models:

LED Housings and Accessories:

Aluminum Enclosures:

For information on our fabrication services, please contact our sales department: [email protected] or call us at (937) 630-3012