Pressure Sensitive Paint

Pressure Sensitive Paint

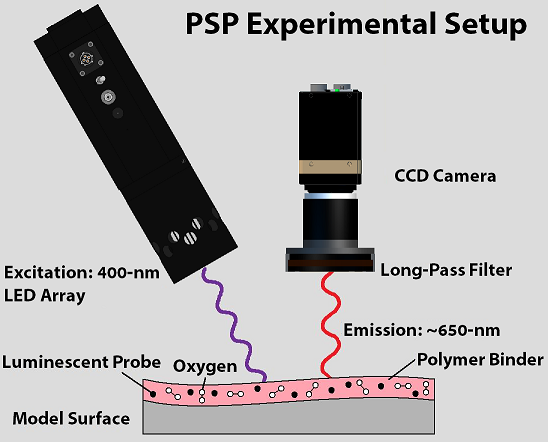

Pressure sensitive paints (PSP) are optical sensors for surface pressure measurements. A paint-like coating is applied to a surface and the luminescence of the paint, excited by an LED lamp of a particular wavelength, is recorded with a camera. The luminescent response is a function of the local barometric pressure at the surface and each camera pixel acts as a pressure transducer.

Unlike pressure taps and transducers, PSP provides virtually limitless spatial resolution and can be easily applied and removed from most test surfaces. Moreover, the optical sampling provides a means for low-cost, non-intrusive, full-field surface pressure and temperature measurements very early in the design cycle to extensively enhance the understanding of the aerodynamics and underlying force and moment data.

The accurate determination of spatially continuous pressure distributions on aerodynamic test surfaces is critical for understanding complex-flow mechanisms and for comparison with computational-fluid-dynamics models.

Pressure taps provide information only at discrete points, and their integration on a test surface is time-consuming, labor intensive, and expensive. In addition, the test-surface aerodynamics and structural dynamics can be compromised by these devices because they may introduce system bias. Finally, pressure taps are prone to failure, particularly for turbo machinery or extreme-temperature applications.

Pressure-sensitive paint technology has emerged as an alternative in determining static and transient surface-pressure fields for aerodynamic applications. In this approach, pressure sensitivity is based on molecular-oxygen (O2) quenching of luminescent molecules dispersed in a film that is coated onto a test surface. Under the appropriate excitation, the entrapped probe species will luminesce with an intensity that is inversely proportional to the O2 partial pressure. Because O2 is a constant fraction of air, this method can be used to determine the local surface pressure.

Wind tunnels from small, academic low-speed wind tunnels to large scale transonic research wind tunnels and hypersonic wind tunnels have utilized PSP for model testing and validation for over 20 years. Today, PSP continues to be a valuable resource in government and commercial testing of aircraft, helicopter, automotive, high-speed train, bridge and architectural models and their components. PSP is also utilized as a tool for film-cooling effectiveness measurements in gas turbine engine blade design.

How Does PSP Work?

A typical PSP is composed of an oxygen-sensitive fluorescent molecule embedded in an oxygen permeable binder. The PSP method is based on the sensitivity of certain luminescent molecules to the presence of oxygen. After application, the PSP is excited with a high-intensity LED, typically a UV 400-nm source. When a luminescent molecule within the PSP absorbs a photon from the LED, it transitions to an excited singlet energy state. The molecule then recovers to the ground state by the emission of a photon of a longer wavelength (red-shifted). When oxygen can interact with the molecule, the transition to the ground state is non-radiative. This process is known as oxygen quenching. The rate at which these two processes compete is dependent on the partial pressure of oxygen at the PSP surface. A higher oxygen quenching rate results in a lower intensity of light emitted from the PSP layer whereas a lower oxygen quenching rate results in a higher intensity of light emitted. The result is an output from a model surface of varying intensities based on the local oxygen concentration which is directly correlated to the local barometric pressure. The output from the PSP is recorded with a sensitive scientific camera through a long-pass filter. To determine this intensity versus pressure relationship, a sample of the PSP is placed in a calibration chamber. The sample is exposed to a series of pressures and temperatures and the luminescent intensity of the sample is recorded.

After images are captured with the camera, they are stored for post-processing. Images are converted from images of intensity variations to images of pressure using a previously determined calibration of the same paint type. From there, false color maps are applied to better visualize the pressure gradients on the model surface. Data can be plotted and compared to pressure taps if present. Typical PSP test are accurate to within 5% of the pressure tap data.

Much like a paint coating, PSP is applied to a surface using a paint gun or airbrush. PSP can be applied in a fume hood or directly to a model in a wind tunnel with proper ventilation.

PSP Error Sources

Major sources of error in PSP data arise from illumination variations and strong temperature gradients across the painted surface. Temperature gradients arise from non-isothermal model materials and temperature changes during data acquisition caused by the wind tunnel or test facility. At low speeds, these errors are more dominant due to the smaller pressure gradients existing on the model surface. To combat these issues, binary PSP is utilized. Binary PSP works by acquiring data from both the oxygen sensitive component and the second component, known as the reference molecule. The emission from the reference and oxygen sensitive molecules are spectrally independent. A color camera is used to separate the signals from the reference and oxygen sensitive components of the binary PSP. From this, two images are acquired (one of the reference and one of the oxygen sensitive component). Taking the ratio of the oxygen sensitive image over the reference image eliminates dependence on temperature. This is due to the reference and oxygen sensitive molecules having the same sensitivity to temperature. By dropping the temperature dependence, an ideal PSP is created where the only dependence is on the pressure change.

Fast-Responding Pressure Sensitive Paint

Traditionally, PSP was used to measure low-frequency or steady-state pressure changes on model surfaces. With LED and high-speed camera technology rapidly advancing, fast-response PSP has also rapidly advanced over the past decade. Rather than acquiring steady-state results with traditional PSP data acquisition, fast-response PSP utilizes paints which respond to pressure changes much more rapidly, leading to accurate, high-resolution time resolved pressure data. With the vast amount of data collected (typically thousands of images per test condition), fast PSP has produced unsteady aerodynamics data like never before. Today, fast PSP can measure pressure fluctuations up to 20 kHz. Data mining these thousands of data points leads to vast improvement of CFD models and complete spatial distribution maps of pressure at selected frequencies. Problems like buffeting and acoustic noise can be studied at depth and resolved with data of the caliber.

Fast PSP Response to Fluidic Oscillator Impinging on Surface

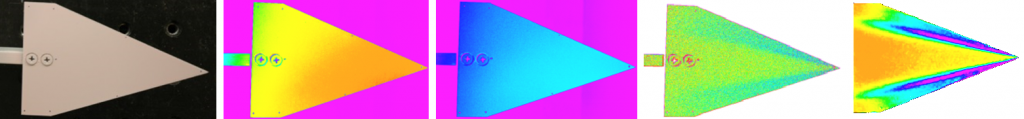

Fast PSP allows scientists to look at rapid pressure fluctuations on model surfaces like never before. Conventional methods of fast pressure fluctuation detection are limited to point measurements. If the sensor is in the wrong spot, it will be missed all together. Using the global data from fast PSP data collection, these fluctuations are brought into view rather easily. The above images show a US model painted with fast PSP, the model under UV illumination (through a long-pass filter to separate the UV light from the paint emission) and finally the processed PSP data with a false color map applied. This is only one in a series of thousands of images.

Global Skin Friction from PSP

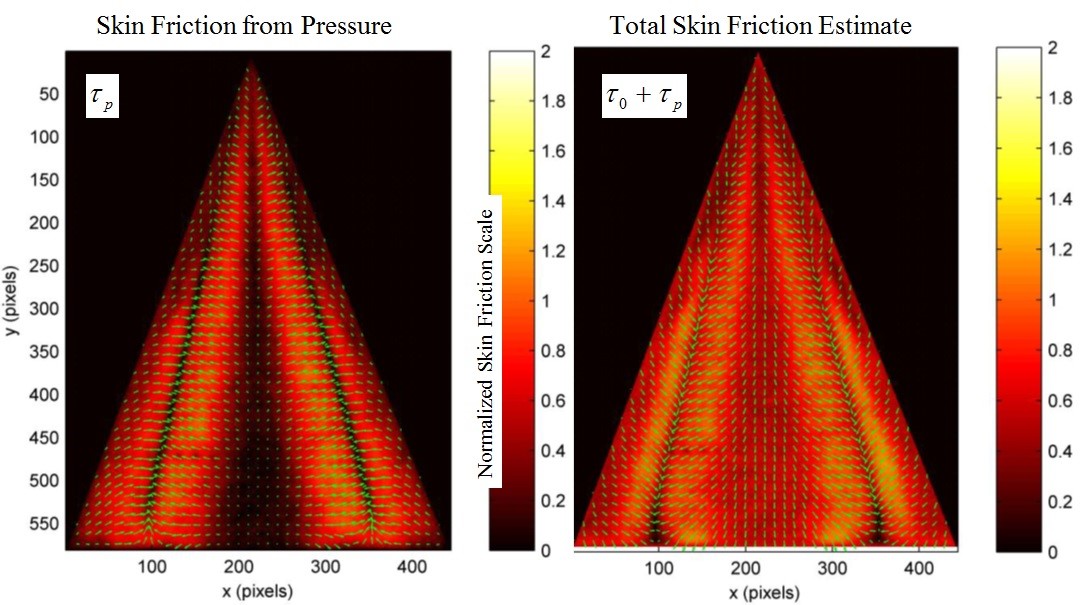

Over the last several years, the extraction of global skin friction fields has been demonstrated from a variety of surface visualization techniques including PSP. These measurements can provide high spatial resolution distributions of relative skin friction from pressure maps as well as extraction of unsteady skin friction from unsteady pressure maps obtained from fast PSP.

The surface pressure gradient field obtained from PSP and the shear field are intrinsically coupled through a vorticity-unsteady mechanism. This coupling can be used to extract skin-friction structures from the surface pressure field.

Pressure Sensitive Paint Products

- ISSI Single-Component Pressure Sensitive Paints

- ISSI Binary Pressure Sensitive Paints

- Pressure Sensitive Paint Base Coatings

- PSP Starter Kit

- Packaged PSP Systems

For ordering information please contact our sales department: [email protected] or call us at (937) 630-3012

For technical support, please contact our support department: [email protected] or call us at (937) 630-3012