Surface Stress Sensitive Film

Surface Stress Sensitive Film

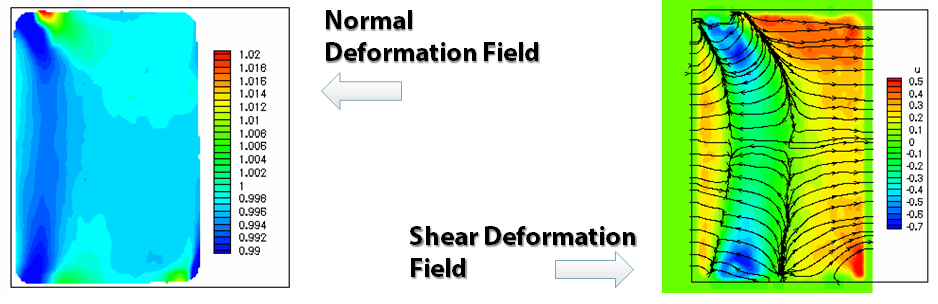

Surface Stress Sensitive Film (S3F) is an optical instrument for measurements of skin friction. The basis of this measurement is an elastic film that deforms under the action of the applied loads. The reaction of the film is monitored by imaging the surface. The film reaction is then modeled using finite element analysis resulting in a continuous distribution of skin friction over the filmed surface.

The surface of the film will undergo a tangential displacement due to an applied tangential load but will not compress or yield. The response of the film may be visualized by considering a series of markers on the surface of the film. The markers are displaced as the film shears and this displacement is a function of the film properties, the shear modulus and thickness. Upon removal of the load the film will return to its original shape.

Upon application of a normal force, the film will deform but will not compress or yield. The local thickness of the film will be modified by the presence of the load near the point of contact. Upon removal of the load, the film will return to its original shape. The stressed film thickness is a function of the applied normal force, the thickness of the film, and the shear modulus. Note that the film responds to gradients in pressure, not changes in static pressure. This can be a significant advantage for several reasons. First, this results in a shear sensor that is insensitive to static pressure. Generally, pressure forces are orders of magnitude larger than skin friction forces and thus the response of the skin friction sensor suffers due to cross-talk between the normal and tangential response. Second, the sensor is a gradient sensor and thus can be tuned for applications that require larger or smaller sensitivity. A more detailed description of the film behavior is included later.

System Configuration

The process of measuring shear is accomplished opticallly measuring the tangential deformation of the film by tracking surface illuminated markers embedded in the layer. These deformations are then converted to forces using a physical stress/strain model of the film.

All three components of deformation can be extracted from a pair images taken by a single high-resolution scientific camera. Two images are acquired, an unloaded or flow-off image and loaded or flow-on image. The ratio of these images is a linear function of film thickness. The tangential displacement measurement is accomplished using the same pair of images. The surface of the film is lightly doped with small particles and the tangential displacement map is obtained by spatially cross-correlating the flow-off and flow-on images.

Packaged S3F Sensors

The chemistry of an S3F layer can be altered or tuned to a specific application, making the S3F a versatile sensor for a wide range of applications from insect locomotion studies to hydrodynamics research to aircraft tire research.

An image of the film is recorded at an unloaded condition and a second image is recorded at the loaded condition. The tangential displacement of the film surface is determined using a cross-correlation between the wind-off and wind-on images. By superimposing the tangential displacement (vectors), a visualization of the flow can be produced. The image is then converted to forces using an FEA model.

FootSTEPS Gait Analysis System

S3F Tire Sensor System

For ordering information please contact our sales department: [email protected] or call us at (937) 630-3012

For technical support, please contact our support department: [email protected] or call us at (937) 630-3012