Fast PSP Applications

Fast PSP Applications

Buffeting and Acoustics

Traditionally, buffet loads on launch vehicles have been determined by using unsteady pressure transducers to measure pressure fluctuations. They are limited however to several hundred locations on a wind tunnel model and pressure fluctuations are then integrated over a specified area. Even with this very large number of sensors, the coverage is insufficient to provide accurate integrated unsteady loads on the vehicle and the coarse spacing of the sensors results in buffet environments that are often conservative in their prediction of buffet loads between the transducers. This results in additional structural weight to cover these conservative environments. Computational fluid dynamics (CFD) is potentially capable of modeling these environments but is currently too slow and not well validated for unsteady loads. (Marvin E. Sellers M. A., 2017 – link below image)

The high spatial resolution of Fast PSP allows for more accurate measurements of buffeting on the launch vehicle. Rather than several hundred data points, fast PSP gives millions of data points. This creates a much more accurate measurement of the loads on the vehicle and an improvement to the CFD model. The cost and weight savings by designing based on Fast PSP buffeting tests results are potentially very large and can reduce the weight of the vehicle, allowing larger payloads.

Cavity Flow

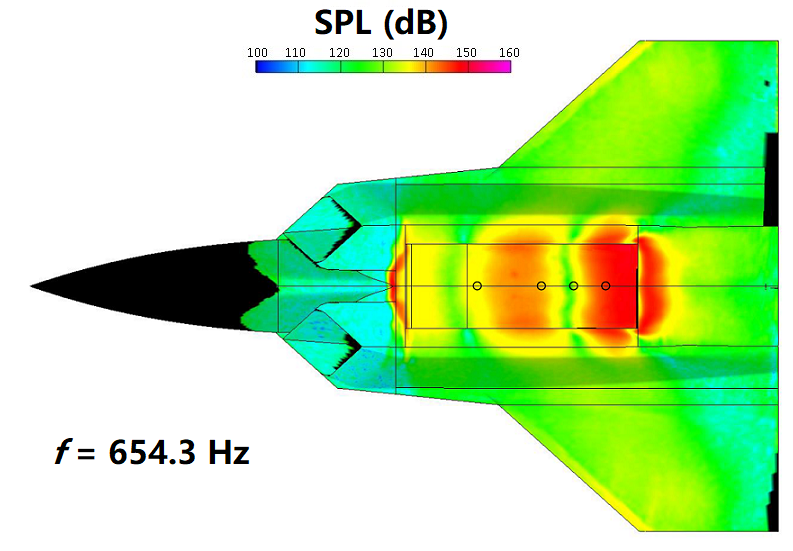

The main area of interest for fast PSP in a cavity is for the research of stores within a cavity. Acoustics and buffeting are real problems for stores or cavity structure. Changing the geometry of the cavity or placing a flow control device in front of the cavity can change the acoustics within by changing the location of the standing waves, also known as Rossiter tones.

Investigation of Passive Flow Control of Cavity Acoustics Using Dynamic Pressure-Sensitive Paint Download

Below, amplitudes of pressure fluctuations (shown as sound pressure levels in dB) are shown up to 5 kHz and their comparison to two Kulite fast pressure transducers. A comparison was done between a baseline (no object upstream) cavity and various flow control devices to mitigate standing waves withing the cavity. A cylinder was demonstrated to be most effective at acoustics mitigation which could only be accomplished with the high spatial resolution and time resolution of fast pressure sensitive paint. Reference link below image.

Investigation of Passive Flow Control of Cavity Acoustics Using Dynamic Pressure-Sensitive Paint Download

The ability to change the location of the standing waves avoids potential damage to stores while in the cavity and to the structure. Flow control was tested for the cavity ceiling to determine the most effective method. Changing the flow changes the location of the standing waves, moving them to an area of less concern for stores.

Rotating Machinery

Acquiring pressure data on rotating machinery such as compressors, turbines, propellers, and helicopter blades can be difficult and expensive. Physical constraints such as mechanical movement, section thickness, and wiring access can preclude the use of taps and the resulting data has limited spatial resolution. Applying pressure sensitive paint (PSP) to the surface enables high spatial resolution surface measurements on helicopter rotor blades, thus allowing more accurate analytical prediction methods to be developed. (Anthony Neal Watkins, 2011 – link below image)

Fast PSP is utilized to image the instantaneous pressure distribution on the helicopter blade as it passes through the field of view of the camera. The blade passage frequency is high and the time it is in the field of view is very small so a fast responding paint is needed to capture the pressure distribution without blurring. A pulsed laser is used to provide high intensity excitation with nanosecond exposure times in the single-shot lifetime data acquisition method.

ISSI Fast Pressure Sensitive Paint

For ordering information please contact our sales department: [email protected] or call us at (937) 630-3012

For technical support, please contact our support department: [email protected] or call us at (937) 630-3012