Calibration Systems

PSP/TSP Calibration Systems

(Product ID: CAL-04, CTC-04)

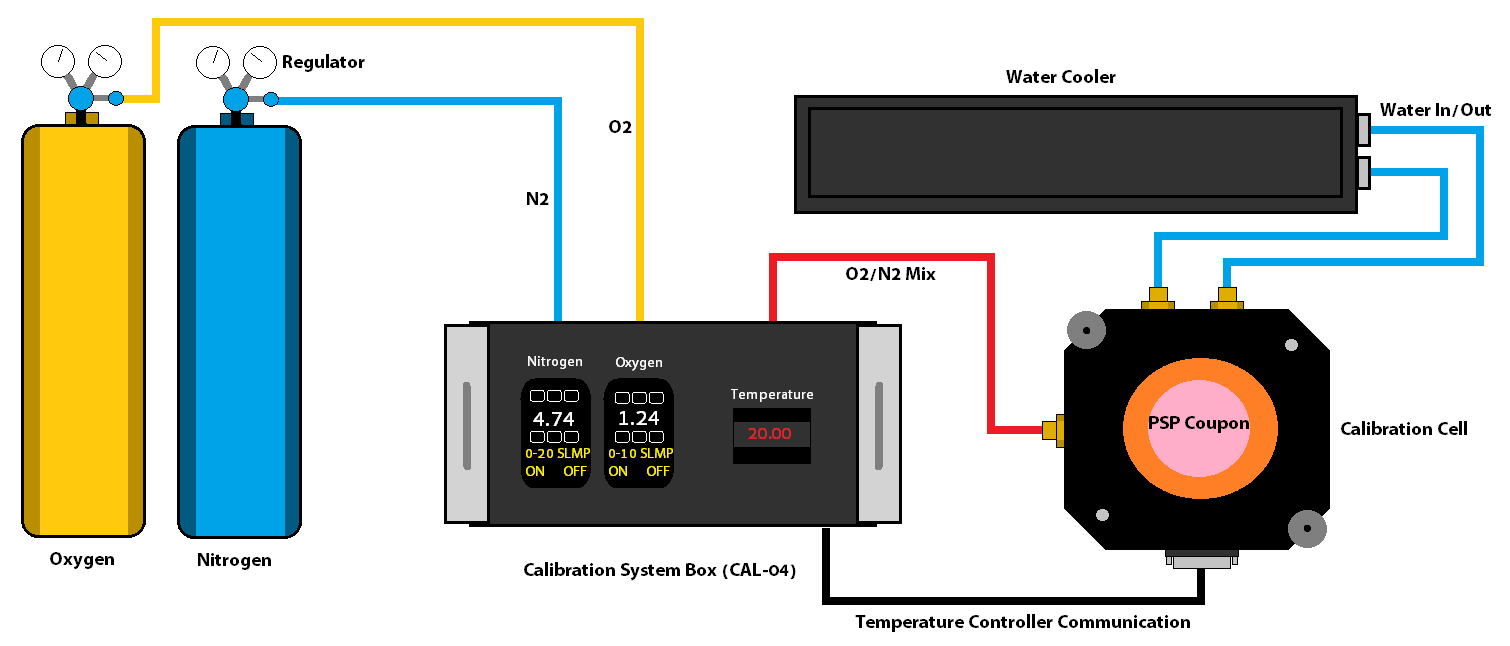

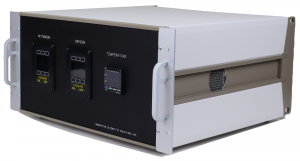

The ISSI Calibration System is a multi-function system designed for controlling the mass-flow of two gases and temperature within a sealed cell. This new evolution of ISSI’s pressure and temperature sensitive paint calibration system utilizes a gas flow design whereby the nitrogen to oxygen mass flow ratio is controlled to simulate pressure. The advantage of this technique is the ability to simulate pressures from approximately 0 to 4.0 bar without the noise and complexity of the diaphragm pump. Nitrogen and oxygen from gas bottles flow into the gas inlet fittings on the calibration box via appropriate dual stage regulators (ISSI does NOT supply bottle gas or regulators). The mixed gas exits the calibration system box via the output rear fitting and then into the calibration head where the gas flows over the sample. The temperature control has been upgraded to provide faster temperature control and improved stability. All of the displays are back-lit and colored for ease of recognition.

The ISSI Calibration System is a multi-function system designed for controlling the mass-flow of two gases and temperature within a sealed cell. This new evolution of ISSI’s pressure and temperature sensitive paint calibration system utilizes a gas flow design whereby the nitrogen to oxygen mass flow ratio is controlled to simulate pressure. The advantage of this technique is the ability to simulate pressures from approximately 0 to 4.0 bar without the noise and complexity of the diaphragm pump. Nitrogen and oxygen from gas bottles flow into the gas inlet fittings on the calibration box via appropriate dual stage regulators (ISSI does NOT supply bottle gas or regulators). The mixed gas exits the calibration system box via the output rear fitting and then into the calibration head where the gas flows over the sample. The temperature control has been upgraded to provide faster temperature control and improved stability. All of the displays are back-lit and colored for ease of recognition.

The calibration system features a simple user interface for control of the system. The software communicates via standard Ethernet. The interface allows the user to remotely control the mixture of the two gases within the cell as well as the temperature within the cell.

Downloads

Calibration System (CAL-04) Datasheet.pdf

Calibration System Operating Instructions.pdf

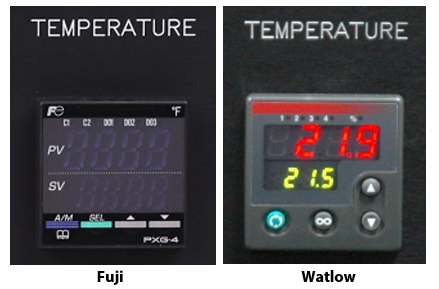

User Interface (Fuji Controllers): PTControl_v2.4.8f.exe

User Interface (Watlow Controllers): PTControl_v2.5.0w.exe

Calibration Post-Processing Software: OMS Calibrate_Licensed.exe

The temperature and pressure (mixed gases) steps can be automated using the interface as well. All data is then output to a log file for post-processing in OMS Calibrate.

For ordering information please contact our sales department: [email protected] or call us at (937) 630-3012

For technical support, please contact our support department: [email protected] or call us at (937) 630-3012