Fast Pressure Sensitive Paints

TurboFIB® Pressure Sensitive Paint

(Product ID: TF-XXX)

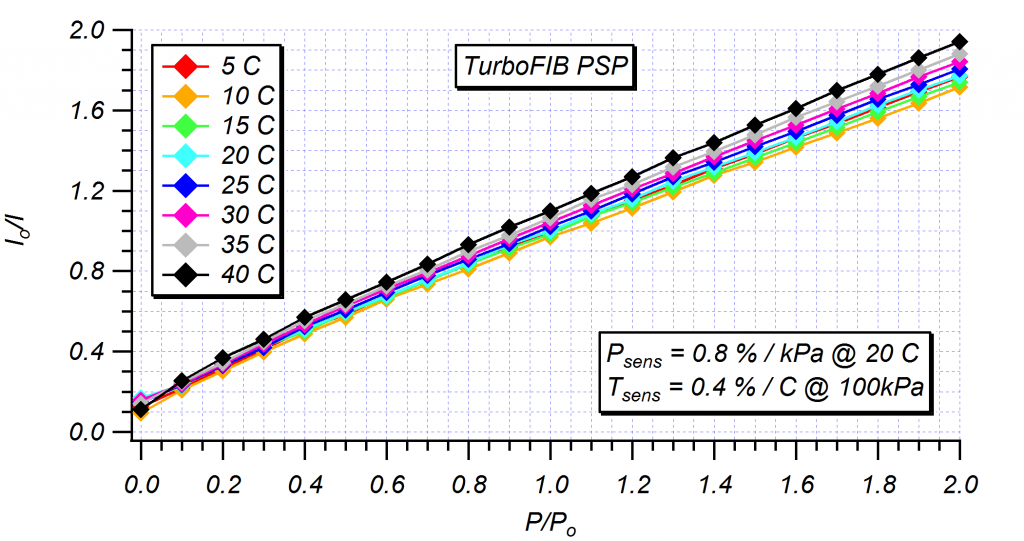

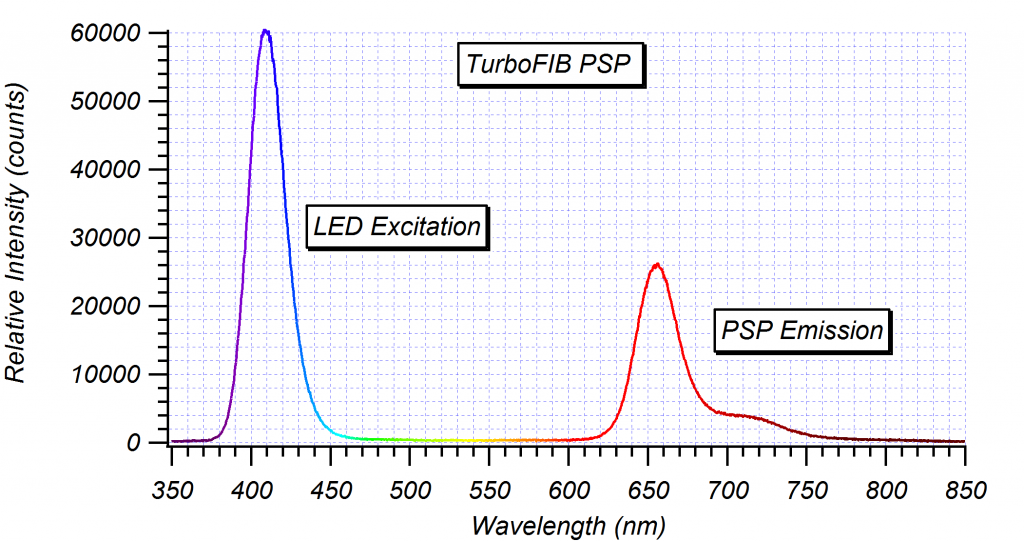

TurboFIB® pressure sensitive paint (PSP) is a single-luminophore, single application PSP formulated to be applied with paint spraying equipment. TurboFIB® provides many of the advantages of UniFIB® PSP, but with faster response (1 kHz) and reduced temperature sensitivity. This paint formulation may be excited effectively from 380-nm to 550-nm, however, 400-nm radiation from ISSI LED modules is recommended for ideal response and pressure sensitivity. The paint may be applied to most surfaces, though it is recommended that plastics and rapid prototyping resins first be coated with SCR-XXX (Screen layer) to protect the surface from solvent damage. FIB Basecoat™ is not recommended for use with TurboFIB®. The calibration of TurboFIB® (shown below) is very stable and repeatable thus TurboFIB® is recommended for advanced/professional PSP users who seek high quality unsteady pressure data.

TurboFIB® pressure sensitive paint (PSP) is a single-luminophore, single application PSP formulated to be applied with paint spraying equipment. TurboFIB® provides many of the advantages of UniFIB® PSP, but with faster response (1 kHz) and reduced temperature sensitivity. This paint formulation may be excited effectively from 380-nm to 550-nm, however, 400-nm radiation from ISSI LED modules is recommended for ideal response and pressure sensitivity. The paint may be applied to most surfaces, though it is recommended that plastics and rapid prototyping resins first be coated with SCR-XXX (Screen layer) to protect the surface from solvent damage. FIB Basecoat™ is not recommended for use with TurboFIB®. The calibration of TurboFIB® (shown below) is very stable and repeatable thus TurboFIB® is recommended for advanced/professional PSP users who seek high quality unsteady pressure data.

Specifications

| Pressure Sensitivity | 0.8% per kPa |

| Pressure Range | 0-kPa to 200-kPa |

| Temperature Sensitivity | 0.4% per °C |

| Temperature Range | 0°C to 50°C |

| Response Time | <1 ms |

| Excitation | 380-nm to 550-nm (400-nm ideal) |

| Emission | 620-nm to 750-nm |

| Photo-Degradation Rate | 1% per hour |

| Shelf Life | 12-months |

| Filter | 610-nm |

| ECCN | EAR99 |

Available quantities: 200-ml, 400-ml, 750-ml

Surface coverage is approximately 1 square meter per liter.

Downloads

TurboFIB® Painting Instructions.pdf

Calibration (PSP-CCD-M): TurboFIB®

Calibration (PCO.1600): TurboFIB®

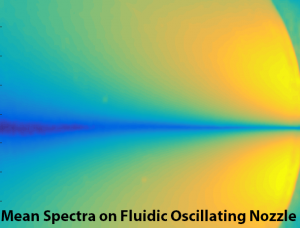

Calbration of TurboFIB® PSP

Emission Spectra of TurboFIB® PSP Excited Using LM2X-DM-400 LED

Porous, Fast-Response Pressure Sensitive Paint

Product ID: FP-XXX)

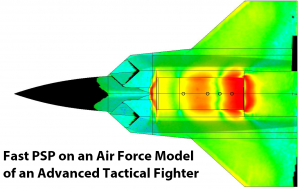

Porous, Fast-Response PSP is a three component, single-luminophore high speed pressure sensitive paint (PSP) formulated to provide high speed response (>10kHz) suitable for unsteady pressure measurements with high pressure sensitivity. The temperature sensitivity of these paints is higher than UniFIB® or TurboFIB™ so this PSP is best suited for isothermal environments. Porous, Fast PSP has been used for several years for buffet and acoustics testing for commercial and military air vehicles, fast-response film cooling and rotating machinery applications for helicopters and gas turbines. This paint comes in three parts. The base layer of Porous, Fast PSP is applied using an HVLP spray gun to the surface of study with a wet application to achieve a smooth finish. Once the base layer is dry, apply part C with paint spraying equipment, the over-spray. The over-spray (part C) may be reapplied more than once.

Porous, Fast-Response PSP is a three component, single-luminophore high speed pressure sensitive paint (PSP) formulated to provide high speed response (>10kHz) suitable for unsteady pressure measurements with high pressure sensitivity. The temperature sensitivity of these paints is higher than UniFIB® or TurboFIB™ so this PSP is best suited for isothermal environments. Porous, Fast PSP has been used for several years for buffet and acoustics testing for commercial and military air vehicles, fast-response film cooling and rotating machinery applications for helicopters and gas turbines. This paint comes in three parts. The base layer of Porous, Fast PSP is applied using an HVLP spray gun to the surface of study with a wet application to achieve a smooth finish. Once the base layer is dry, apply part C with paint spraying equipment, the over-spray. The over-spray (part C) may be reapplied more than once.

Specifications

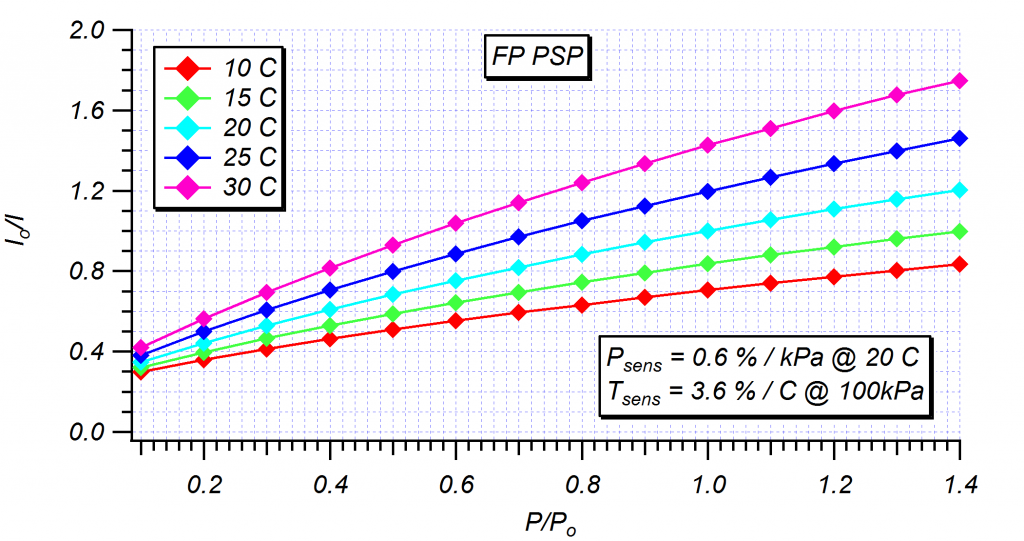

| Pressure Sensitivity | 0.6% per kPa |

| Pressure Range | 0-kPa to 200-kPa |

| Temperature Sensitivity | 3.6% per °C |

| Temperature Range | 0°C to 80°C |

| Response Time | <100 µs |

| Excitation | 380-nm to 550-nm (400-nm ideal) |

| Emission | 600-nm to 750-nm |

| Photo-Degradation Rate | 1% per minute (Excitation) |

| Shelf Life | 3-months |

| Filter | 610-nm |

| ECCN | EAR99 |

Available quantities: 100-ml, 200-ml, 400-ml, 750-ml

For the 100-ml quantity, the coverage is about 1 square foot.

Downloads

Porous, Fast-Response PSP Datasheet.pdf

Porous, Fast-Response PSP Painting Instructions.pdf

Calibration: Fast Porous PSP

Calbration of Porous, Fast Response PSP

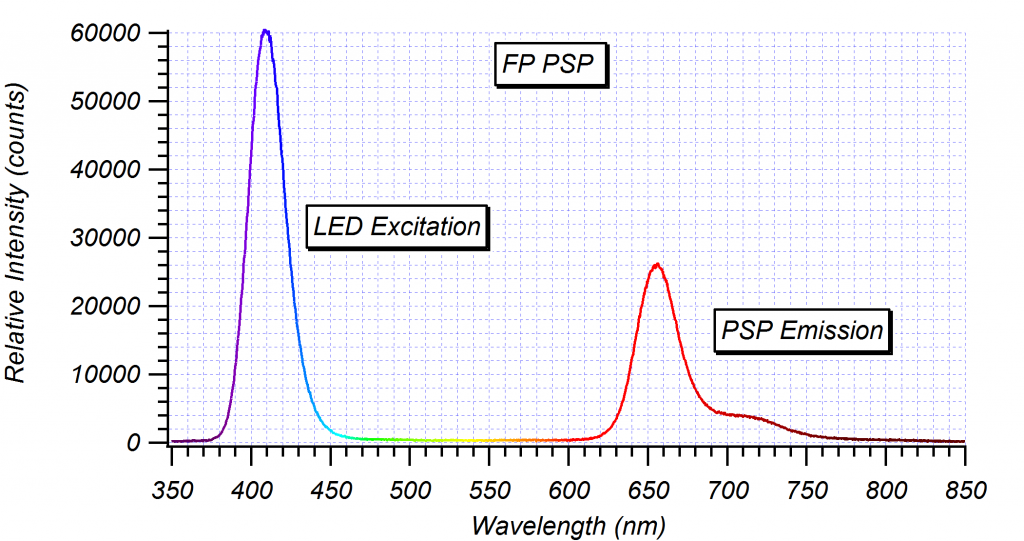

Emission Spectra of

Porous, Fast Response PSP Excited Using LM2X-DM-400 LED

Publications

- Dynamic Pressure Sensitive Paint Demonstration in the AEDC Propulsion Wind Tunnel 16T

- Investigation of Passive Flow Control of Cavity Acoustics Using Dynamic Pressure-Sensitive Paint

- Investigation of Transverse Jet Injections in a Supersonic Cross-flow Using Fast Responding Pressure-Sensitive Paint

For ordering information please contact our sales department: [email protected] or call us at (937) 630-3012

For technical support, please contact our support department: [email protected] or call us at (937) 630-3012