Binary Pressure Sensitive Paint

Binary Pressure Sensitive Paint

Major sources of error in PSP data are due to illumination variations and temperature changes during the data collection period while the wind tunnel is running. Blow-down type wind tunnels will change temperature during the course of a run while closed-circuit or continuous wind tunnels are more stable with temperature. Errors in pressure measurements taken at low wind speeds are largely the result of temperature gradients on the model surface. These temperature gradients can be the result of model construction, tunnel operation, or fluid dynamics.

A rapid prototype model, for example, is constructed using an internal metal structure and a polymer resin. The thermal signature of the internal structure is apparent when the surface of the model is subjected to a heat flux. The model is exposed to a heat flux due to changes in tunnel Mach number. This condition is most apparent during tunnel startup. Temperature errors can be minimized by using temperature controlled tunnels and constructing the model from materials with high thermal conductivity like aluminum or stainless steel. Model construction and tunnel operation are key considerations for effective low-speed PSP measurements. Illumination variations can be caused by non-stable output from LEDs and by vibrations of the model or camera relative to one another. To the camera, these changes are interpreted as pressure changes.

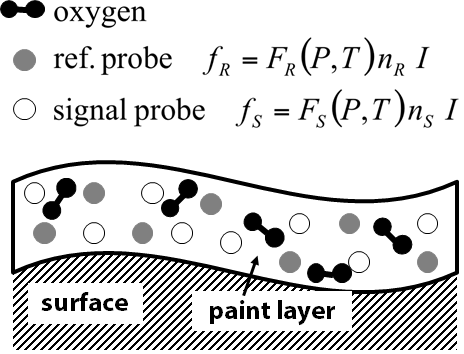

A way of dealing with the temperature errors is to add a second component to the PSP. This is known as Binary PSP. What Binary PSP adds that single-component PSP lacks is the ability to correct for temperature and illuminiation induced errors. Binary PSP works by acquiring data from both the oxygen sensitive component and the second component, known as the reference molecule.

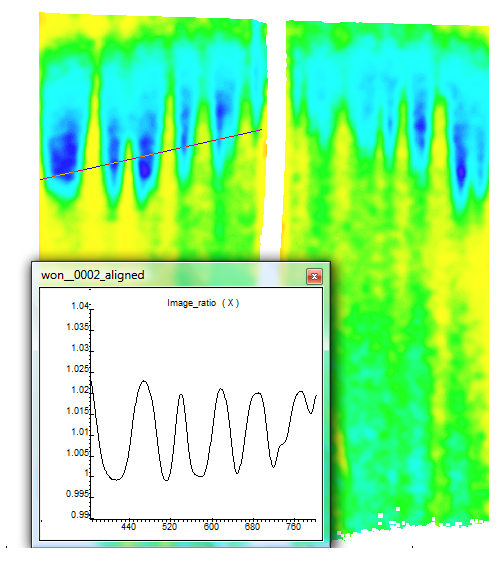

The emission from the reference and oxygen sensitive molecules are spectrally independent. A color camera is used to separate the signals from the reference and oxygen sensitive components of the Binary PSP. From this, two images are acquired (one of the reference and one of the oxygen sensitive component). Taking the ratio of the oxygen sensitive image over the reference image eliminates dependence on temperature. This is due to the reference and oxygen sensitive molecules having the same sensitivity to temperature. By dropping the temperature dependence, an ideal PSP is created where the only dependence is on the pressure change.

The goal is to use the luminescence of the reference probe to correct for variations in the luminescence of the signal probe (the pressure sensor) which are due to variations in illumination. This is accomplished by taking a ratio of the luminescence of the signal probe to the luminescence of the reference probe. Since the luminescent signal from each probe is a linear function of the illumination, the ratio of the signals from the probes naturally eliminates illumination variations from the equation.

This signal to reference ratio can vary spatially on the model surface because the solubility of each probe in the solvent system, as well as the polymer binder, is not equal. Since the spatial distribution of the probe concentration is constant on the painted surface this problem is resolved by dividing the wind-on ratio by a wind-off ratio. This ratio of ratio’s approach is used extensively for Binary PSP systems.

ISSI Binary Pressure Sensitive Paints

For ordering information please contact our sales department: [email protected] or call us at (937) 630-3012

For technical support, please contact our support department: [email protected] or call us at (937) 630-3012